This is my tumbling/polishing experiment.

I wanted to test how well 3D-printed objects can be polished using silicon carbide sand.

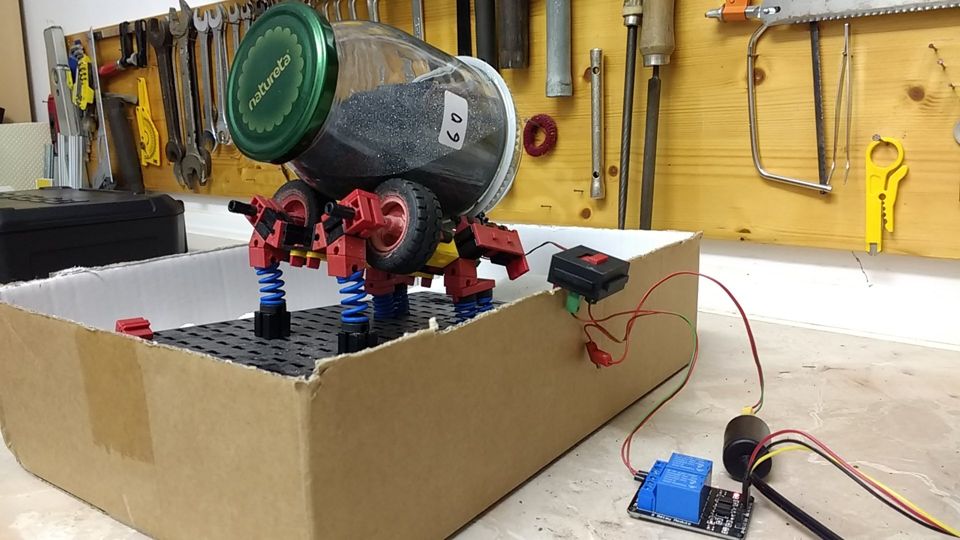

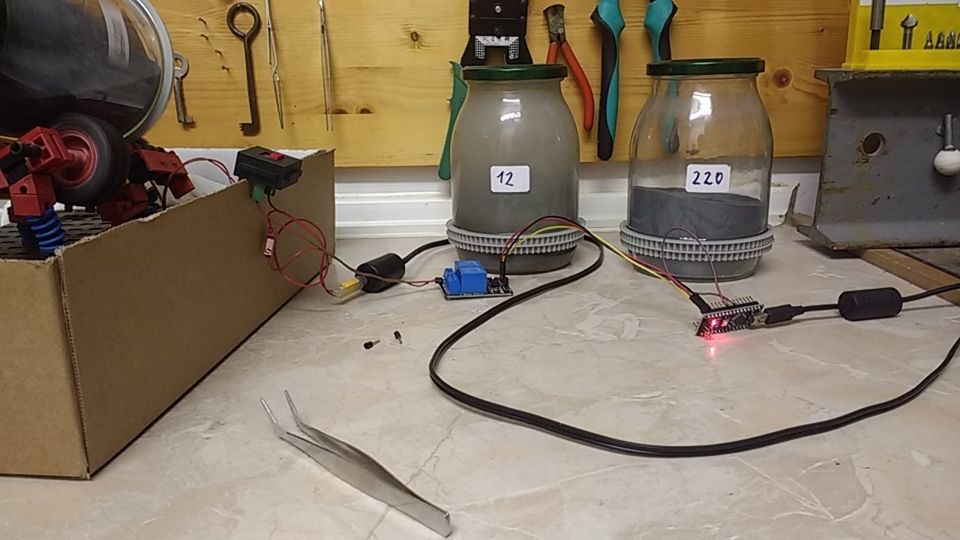

I put the parts and the sand in a jar and my machine spins the jar for hours.

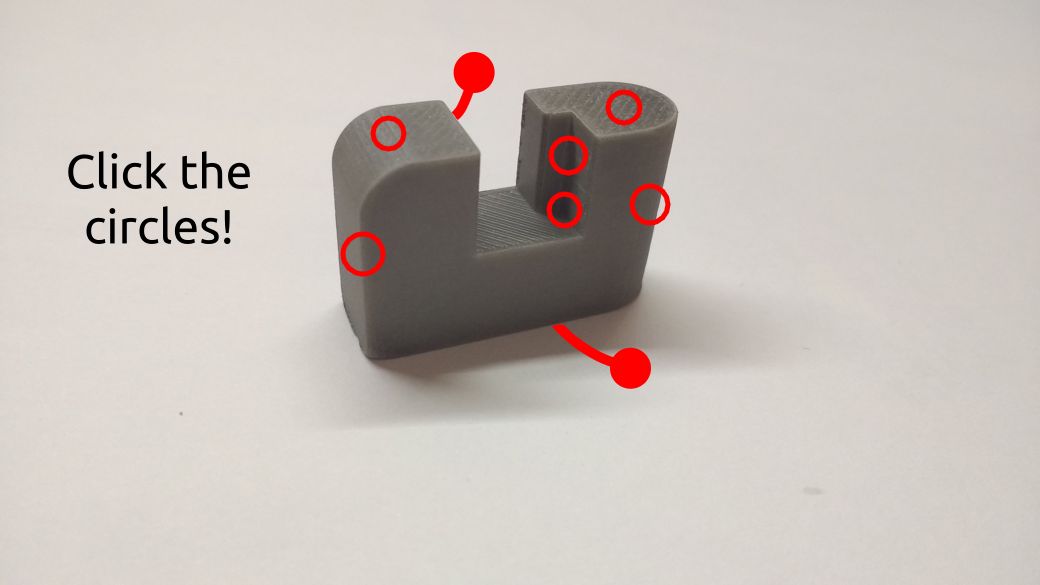

On this website you can see the close-ups of different parts of the object,

at different stages through the polishing process.

Click on markers the image to see the results! Or use the links below.

Download all images (36MB)

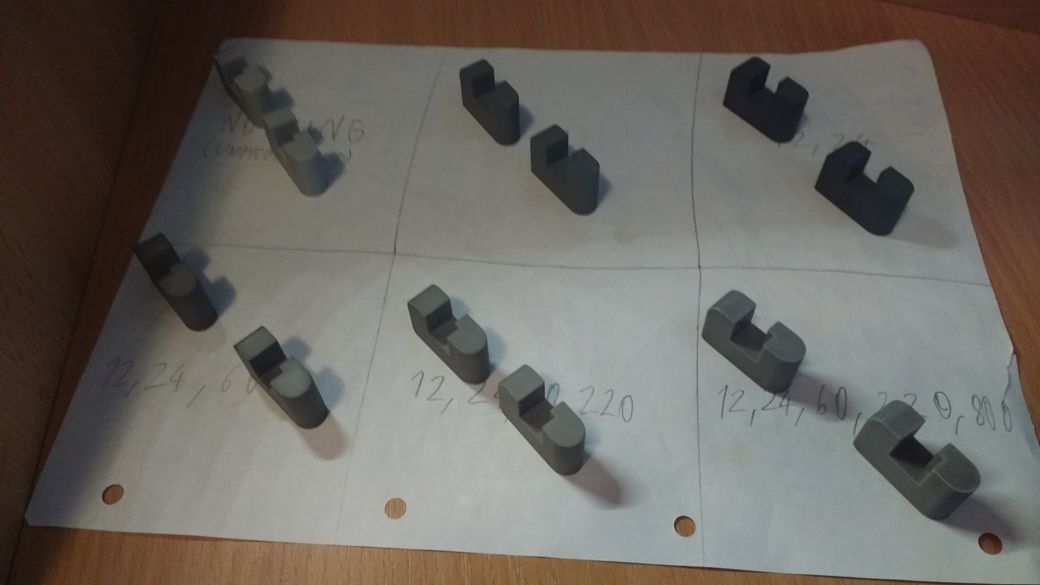

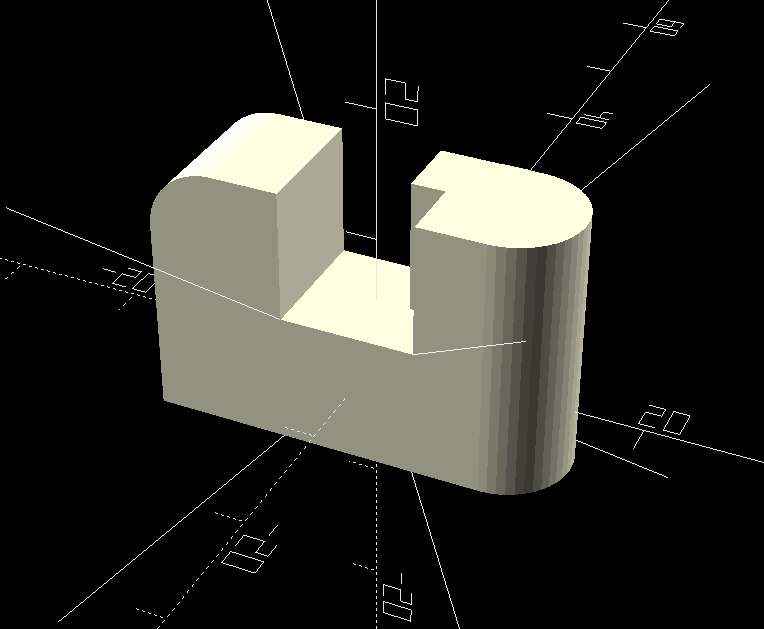

I designed the model specifically for this experiment.

In hindsight, I should have made the middle gap narrower, so the samples can't accidentally get assembled together.

Creality Ender 3 (purchased november 2018)

Each sample was printed individually, in the same conditions, using the same gcode. Printing duration is 1 hour per sample.

Gray OWL PLA

A few days before printing, this filament was in a dehumidifier at 43°C for 5 hours.

The idea for the tumbler came from here, however I built my own out of Fischertechnik and only 3D printed the big gear.

I picked polishing durations for the experiment according to instructions on Thingiverse for "extremely smooth surfaces".

I bought silicon carbide here.

[1] Somewhere during the first 6 hours, the motor broke. I fixed it and reset the timer. So the actual tumbling time is between 24 and 30 hours.

[2] During this tumble, 2 of the samples got assembled together into a "plus" configuration, so their polish job may be uneven.

[3] I noticed that F 220 granularity, my samples did not sink much into the sand, they were mostly rolling along the top.

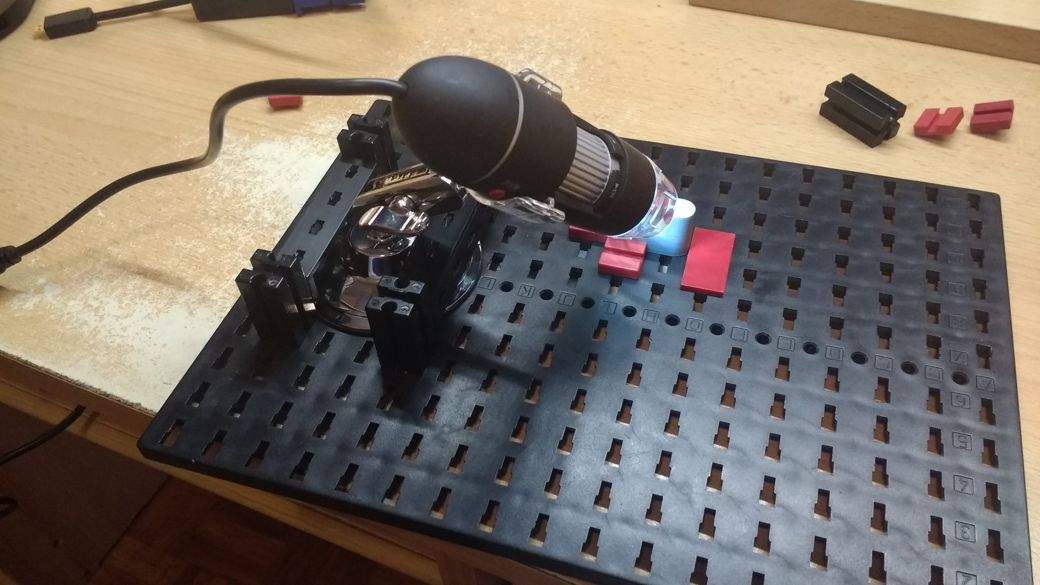

BW-400X Digital Microscope

The microscope mount was firmly attached to the Fischertechnik base plate, so I was able to capture all samples from the same perspective.

I probably need to polish for a longer duration of time.